Aluminum Anodizing

What is Anodizing?

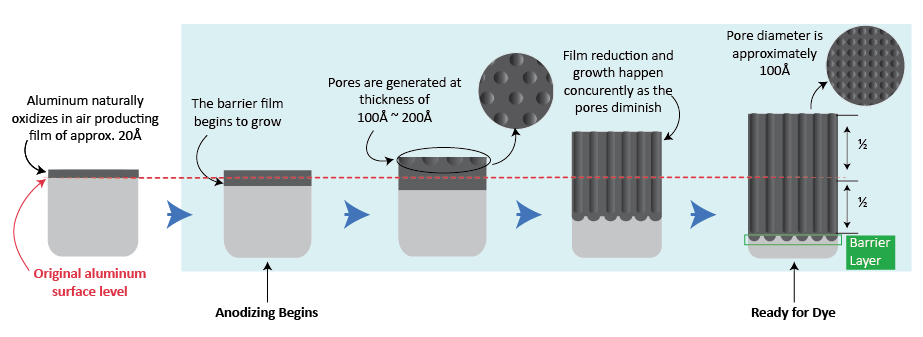

To anodize an aluminum extruded product is to subject the aluminum to an electrolytic action in order to coat it with a protective or decorative film. This process converts the surface into a decorative, durable, corrosion-resistant, anodic oxide finish and it works exceptionally well on aluminum products.

Anodizing is accomplished by immersing the aluminum into an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized.

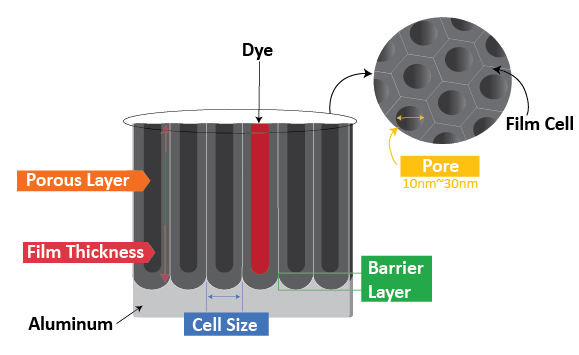

The anodic oxide structure originates from the aluminum substrate and is composed entirely of aluminum oxide. This aluminum oxide is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel. It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing.

Anodizing Process Flow

Kromet aluminum extrusions go through the following anodizing process. After the cleaning stage, parts will either receive an etch or bright dip pre-treatment before moving to the anodize stage.

*Etch pre-treatment chemically abrades the surface to make it uniform and reduces the natural shine of the aluminum. This gives the surface a uniform silver color that gives a rich aesthetic.

*A bright-dip treatment chemically shines the surface and increases gloss and reflectivity. It is typically used in conjunction with aluminum polishing to give a mirror like finish or a high gloss finish with colors.

After moving through the anodizing stage the parts are ready to be dyed and sealed to achieve the desired color and finish. The amount that the pores are filled determines the color saturation.

Types of Anodizing Processes

- Protective & Decorative Coatings

Protective or functional coatings require a higher coating thickness that can affect the visual aesthetic but which offer a higher resistance to corrosion and abrasion resistance. Decorative coatings have good performance characteristics but favor thinner coatings for a better visual appearance

- Architectural Class I (Type I) - Chromic Acid Anodize

Type I anodizing provides the thinest anodic coat out of the two architectural classes offered by Kromet. However, it still provides the same level of corrosion protection as Type II. The thinner coat makes Type I ideal for parts with tight tolerances as it will not impact dimensions. It is also non-conductive, provides a base for paint, and is an excellent choice for welded parts and assemblies.

- Architectural Class II (Type II) - Sulfuric Acid Anodize

Type II anodizing is the most common method used for anodizing. Sulfuric acid films are porous in nature and are ideally suited for producing colored surface finishes on aluminum extrusions. It is strong, offering a harder finish compared to Type I, provides resistance to abrasion. It has a clearer finish which allows for a greater variety of dye colors and once sealed it resists color loss.

Types of Finishes Available

Kromet can also work with you to develop custom colors / finishes based on your project specifics.

- Clear (no pre-treatment)

- Clear Bright

- Satin Etch

- Matte Satin Etch

- Beaded & Satin Etch

- Brushed Stainless

- Brushed Nickel

- Gloss Black

- Matte Black

- Black Stainless

- Titanium Bronze

Racking

Racking is actually the first step in the anodizing process and serves two important functions 1) to carry the parts through the anodizing process and 2) to provide a secure electrical connection to the power supply during the anodizing step.

Parts of a rack:

- Carrier

- Main Bar (Aluminum)

- Rods (Titanium)

- Component (Aluminum)

- Spline of small box section

- Upper sprint clip (Titanium)

- Lower fixed clip (Titanium)

- Lower box section (Titanium)

What Sized Parts Can be Anodized?

Kromet's standard racks can accommodate parts up to 72" long, parts up to 120" long can be considered with customized racking.

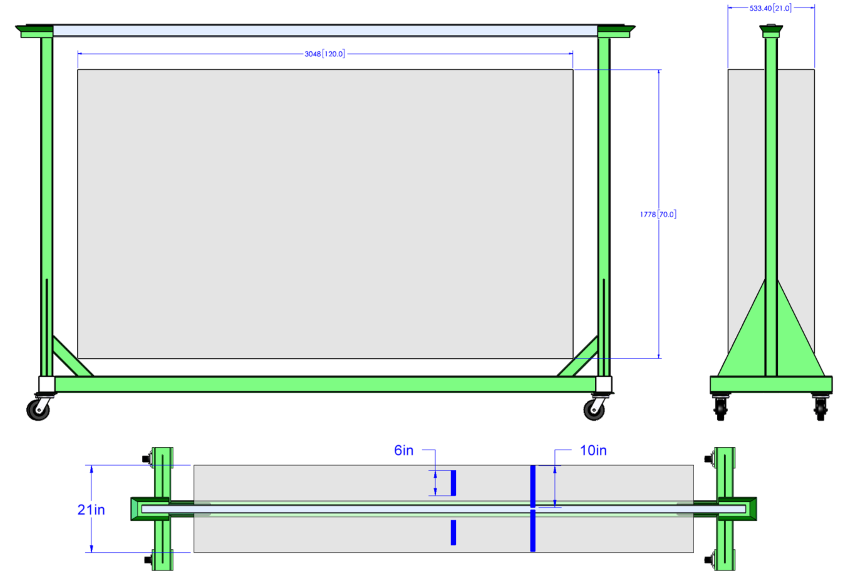

- Parts need to fit within the transparent box (120 x 21 x 70) shown in the diagram below. Constraints are based on the smallest anodizing tank and the liquid level within the tanks.

- Parts are typically racked on 2 sides, usually in widths <10". Special cases of larger widths can be reviewed.

- Parts shorter than <34" can be racked 2 rows high, doubling the number of parts on a rack.